Beam Dyeing Machine

Tex Fab Manufactures HTHP Beam dyeing machine and economical beam dyeing machine of capacity upto 500Kgs/batch.

Application :

Application :

• For dyeing and bleaching of all types of fabrics in open width form.

Advantages:

• As the fabric wound on perforated beams is static, the even penetration of dye liquor ensures level dyeing and avoids damage to the fabrics. No wrinkles and crease marks on the fabrics. Suitable for delicate fabrics as well as heavy suiting’s.

• The machine is suitable for working pressure upto 5 bar and temperature upto 1350C

• Provided with ‘Airpad’ system for static pressure thus reducing the M:L ratio. (1:6 upwards)

• High capacity high efficiency centrifugal pump with flow reversal device for both into out and out to in flow for achieving uniform dyeing results.

• Internal heat exchanger of seamless tubes increases the heat transfer efficiency and causes least pressure drop in liquor flow.

• Machine with various diameters and width with one or two beam in series are available as per customer’s requirement.

Pneumatic Press

Texfab Manufactures chamber type forced circulation Hot air dryer for dyed yarn packages from capacity 25 to 500 Kgs/batch. The machine consists of:

Texfab Manufactures chamber type forced circulation Hot air dryer for dyed yarn packages from capacity 25 to 500 Kgs/batch. The machine consists of:

Salient Features :

• Our pneumatic press consist of header with movement in X and Y axis.

• Pressing head and guide rods are provided as per the application to meet the particular needs of any pressing process.

• Gear motor is provided in the trolley for easy movement of the carrier.

Hot Air Dryer

Our recirculatory hot air dryer-chamber type for yarn in packages, is an economical alternative to RF dryer . It is recirculatory type for higher thermal efficiency. The machine is fully controlled via programmer. Drying cycle for cotton is 41/2 hours. The hot air dryer machine consists of:

Our recirculatory hot air dryer-chamber type for yarn in packages, is an economical alternative to RF dryer . It is recirculatory type for higher thermal efficiency. The machine is fully controlled via programmer. Drying cycle for cotton is 41/2 hours. The hot air dryer machine consists of:

• Cabinet: Fabricated from heavy duty angle Frame with gauge S.S.Sheet inside and M.S.Sheet from outside with powder coating and sliding door.

• Insulation : Cabinet and door are insulated Glass wool.

• Blower Fan : A centrifugal blower with motor. The blower force circulates hot air through the yarn packages and the exhaust is partly re circulated.(Optional) The blower motor is fitted with A.C. inverter drive for soft start and flow control.

• Radiator : Steam or thermik fluid Radiators are provided to heat the chamber temperature upto 120°C. Hot air generator working on LPG/CNG can also be supplied where required.

• Temperature Control : Microprocessor based time-temperature programmer is provided to control the inlet air temperature and temperature indicator for outlet air.

• S.S. rectangular Trolley carrier with poles and special locking nuts for loading the yarn packages into the chamber.

Salient Features :

• Gives uniform drying results. Drying cycle for cotton with 45% residual moisture is 41/2 hours.

• Economical alternatives to RF dryer. Both capital and operating cost less.

• Almost no maintenance. Simple to operate and maintain.

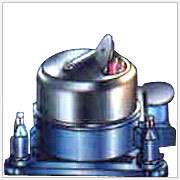

Centrifuge Hydro Extractor

We expertise in manufacturing high quality Centrifuge Hydro Extractor that have high rotating speed for quick and maximum hydro extraction. The high production capacity and very low power consumption makes this machine must for every yarn dye house. Robust in structure, these textile processing machines are compact in size and occupies very less floor space. Our Centrifuge Hydro Extractor are available in different capacities as per the requirement of the customer.

We expertise in manufacturing high quality Centrifuge Hydro Extractor that have high rotating speed for quick and maximum hydro extraction. The high production capacity and very low power consumption makes this machine must for every yarn dye house. Robust in structure, these textile processing machines are compact in size and occupies very less floor space. Our Centrifuge Hydro Extractor are available in different capacities as per the requirement of the customer.

Application : Used for hydro extraction of dyed yarn packages in a short time and at low cost.

Salient Features :

• Centrifuge hydro extractor rotates at very high speed which results in quick and maximum hydro extraction.

• AC Inverter drive is used for soft start and dynamic braking.

• For vibration free running it is provided with unique four point shock absorption system.

• The machine is sturdily built and dynamically balanced to high accuracy.

Technical Specification:

• Model size : 24" 36" 48" 60"

• Approximate loading capacity (polyester) : 27 kg. 45 kg. 63 kg. 90 kg.

Centrifuge Hydro Extractor for Fabrics & Fibre cake

We offer our clients basket type hydro extractor that are either semi open or fully open. These machines are mostly used for hydro extraction of fabrics, hanks, tops and more. Our machines are easy to operate and facilitate direct loading and unloading of fabric in rope form in to the basket from overhead hoist. High in durability and functionality, these machines are sturdily built and dynamically balanced to high accuracy. Our Centrifuge Hydro Extractor is available in diverse specification as per the requirement of our esteemed customer.

Salient Features :

• Centrifuge hydro extractor rotates at very high speed which results in quick and maximum hydro extraction.

• AC Inverter drive is used for soft start and dynamic braking.

• For vibration smooth operation, the machine is provided with unique four point shock absorption system.

• Opening and closing of lid done by pneumatic cylinder.

• The machine is sturdily built and dynamically balanced to high accuracy.

• All parts coming in contact with water and textile are made from stainless steel.

• Available in different sizes and capacities according to customers' requirements from 24" to 72" diameter baskets.

Yarn Conditioning Machine

The advantages of yarn heat setting:

The advantages of yarn heat setting:

• Yarn relaxation gives luster and soft feel.

• Twist setting and stabilization

• Better dye affinity

• Snarling and kinking during unwinding process can be eliminated.

How does it work:

Texfab make yarn steaming yarn conditioning machine of yarn. It is suitable to work on high temperature at 1350C and 3.5 bar pressure. The material of construction is S.S or M.S with optional S.s cladding inside for long life. The autoclave is provided with limpet coil on outside. A water ring vacuum pump is provided with the machine to give maximum vacuum inside up to 650mm of mercury. The yarn conditioning machine are supplied in various capacities from 50Kg to 1000kgs per batch of yarn in cheese or hank form. The yarn carrying and yarn charging trolleys are made as per customer’s requirement to accommodate the maximum material and different loading arrangements.

Autoclave is fully automatic and controlled through microprocessor based programmer.

Radio Frequency Dryer

In a radio frequency heating/drying system, the RF generator creates an alternating electric field between two electrodes. The material to be heated / dried is conveyed between the electrodes, where an alternating energy field causes polar molecules in the material to continuously reorient them to face opposite electrodes much like the way bar magnets move to face opposite poles in an alternating magnetic field. Friction resulting from this molecular movement causes the material to rapidly heat throughout its entire mass.

In a radio frequency heating/drying system, the RF generator creates an alternating electric field between two electrodes. The material to be heated / dried is conveyed between the electrodes, where an alternating energy field causes polar molecules in the material to continuously reorient them to face opposite electrodes much like the way bar magnets move to face opposite poles in an alternating magnetic field. Friction resulting from this molecular movement causes the material to rapidly heat throughout its entire mass.

Features of RF Drying :

• Uniform heating resulting in level drying and controlled moisture content within ±1%.

• Environment friendly. Clean and safe. No effluents and No flues.

• Easy to feed, operate and maintain.

• No need of steam or hot air. Self contained unit.

• Superb consistent quality of dried material for feel and appearance. No chance of contamination, physical damage or colour migration.

• Instant drying process. No startup and shutdown cost.

Application :

• The RF dryer is widely used in Textile industry all over the world for drying the materials after bleaching, dyeing, mercerizing or wet processing after the initial hydro extraction process in a centrifuge to remove excess water.

• Any textile material in the form of fibres, Cheeses, cones, hanks, tows & tops and fabrics can be dried in a RF dryer and over the years this technology has increasingly become an accepted and preferred method for drying.